Popis

Na českém překladu pracujeme.

Railcar builders have been using relays to control equipment for years. During train maintenance, relays and devices such as lamps, door push-buttons or else are often exchanged before their end of life or when they are no longer working. Moving from schedule-based to condition-based maintenance saves significant maintenance costs for train operators.

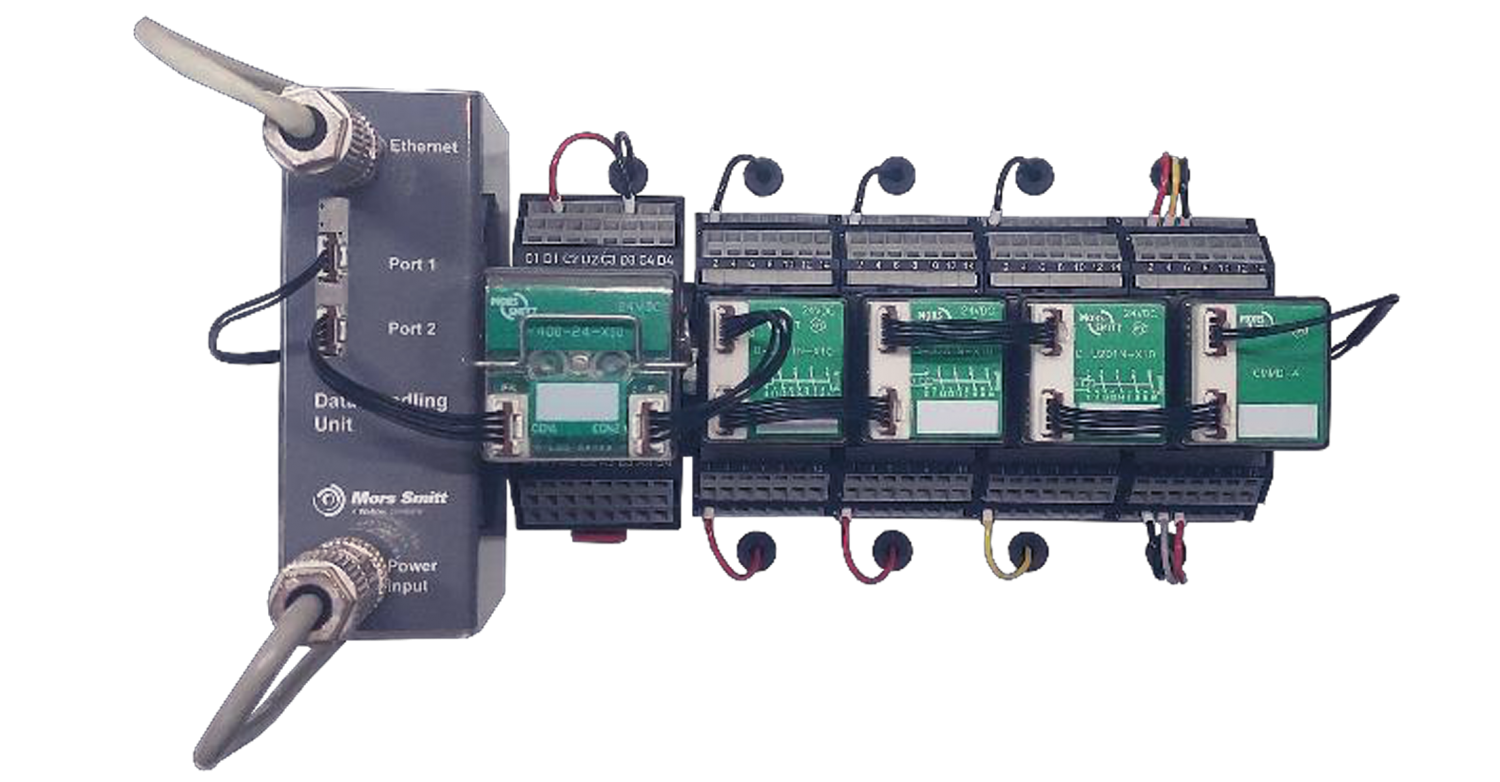

Mors Smitt™ smart Relay Monitoring System is developed to analyze the condition of relays and connected devices in real-time and identify the accurate timing for part replacements. The result: reduced service costs and increased train control availability.

To enable predictive maintenance system includes:

– Voltage Measurement Module (VMM) to monitor the voltage per relay contact

– Current Measurement Module (CMM) to monitor the current per relay contact

– Data Handling Unit to connect up to 50 relays/devices (daisy chaining possible):

- Seven days of data storage capacity

- Serial bus configuration allows DHU, connected relays and modules to communicate with each other

- Data output are easily exportable to the train control management system or other computer devices in a variety of formats (.CSV, .SQL).