Popis

Funkce

- High sensitivity (0.1% of In)

- Tuned to 150 Hz or 180 Hz

- Fundamental & HF noise suppression

- Optional reset functions Instantaneous (Fast), definite time, count down

- 40-300V DC auxiliary supply Power supply fail relay drops out if the auxiliary supply fails.

- Optional 20-70V DC supply

- Low CT burden & high thermal rating

- Optional 1A or 5A CT input

- Instantaneous pick up LED

- Configurable output contacts

- 0-31s time delay (125ms steps)

- Push button / electrical flag reset

- Non-volatile trip indication

- Multi voltage inhibit / enable & flag reset inputs

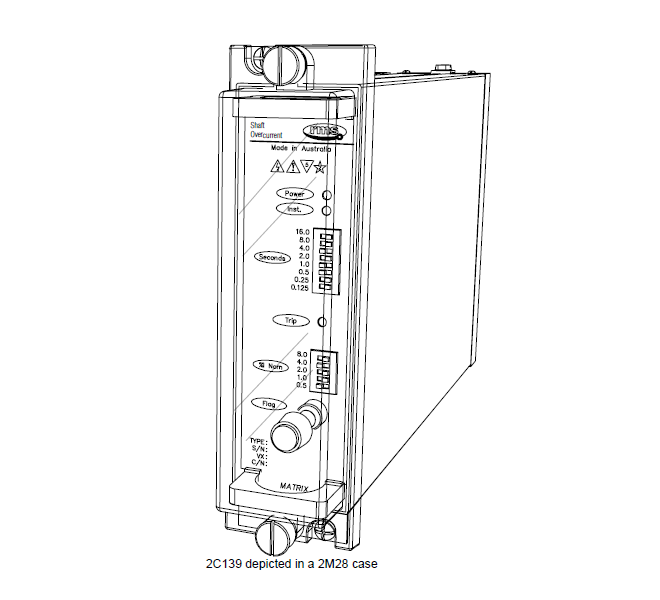

- Size 2M draw out case

Aplikace

If the bearing insulation on rotating machines breaks down, the voltage induced between the shaft ends, due to machine dissymmetries, creates a shaft current that can damage the bearings. The level of damage depends on the magnitude & duration of the shaft current. It is therefore desirable to provide sensitive protection that can detect shaft currents of 1A or less.

The shaft current measurement principle enables more sensitive protection than shaft voltage measurements or vibration monitoring. Vibration monitors only operate after bearing damage has occurred. By applying the shaft overcurrent protection relay type 2C139 together with a special current transformer, the machine can be tripped & the cause of the bearing insulation breakdown determined before the bearing is damaged.

Rejection of the fundamental component is important where the shaft current transformer is exposed to large fundamental leakage flux from the machine. The 2C139 relay may be employed to overcome this problem by monitoring the third harmonic component.