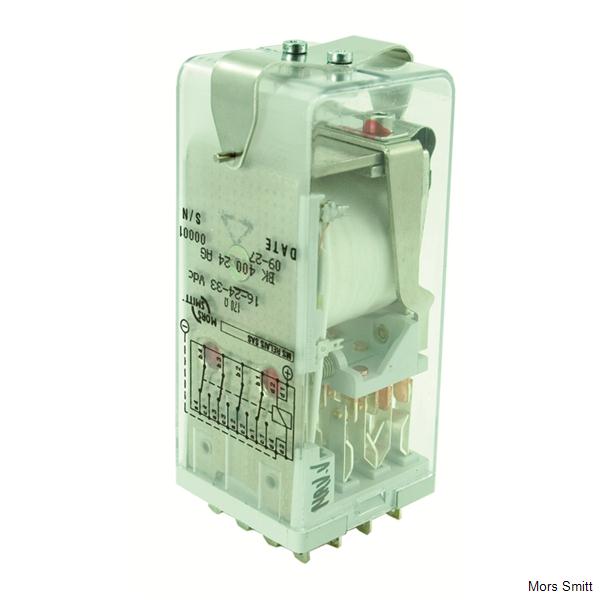

Description

The BK 400 safety critical, heavy duty and weld resistant relay has 4 double make / double break C/O contacts (form Z). Weld no transfer and silver tin oxide safety contacts are standard. The plug-in design offers secure locking feature for maximum ease of maintenance (no wires need to be disconnected or other hardware removed for relay inspection or replacement). The resistance to impact and vibration is conforming the standards for Railway Transported Equipment. Positive mechanical keying of relay to socket is built into relay and socket during manufacture and terminal identifications are clearly marked on identification plate that is permanently attached to the relay. The BK 400 is pluggable in the following sockets: EA 102 B, EA 102 BF, EA 103 BF, EA 104 B, EA 104 BF, EA 105 BF, EA 112 BF.

Application

The BK relay is designed for safety critical applications where a high degree of resistance to welding is required. Stationary contacts are silver tin oxide. Mobile contacts are hard silver laminated to copper. In a power interruption situation relay armature will assure a “safe” position. This is due to the strength of the 2 compressed springs which pushes the armature back into

the rest position.

the rest position.

Features

-

Instantaneous • Safety critical

-

Weld resistant

-

Weld no transfer safety contacts standard

-

Plug-in design with secure locking feature

-

4 double make / double break C/O c ontacts (form Z), 12 A

-

Contact life (mechanical) of 100 million cycles

-

-40 °C…+80 °C operating temperature

Benefits

-

Proven reliable in heavy duty application

-

Weld no transfer • Long life cycle

-

Easy to maintain and replace

-

Used in safety critical application

-

Low life cycle cost

-

No maintenance

Railway compliancy

-

NF F 62-002 Rolling stock- Instantaneous relays contacts and sockets

-

NF F 70-031 section 7.1.2. and 7.1.3 for weld resistant contacts)

-

NF F 16-101/102 Fire behaviour – Railway rolling stock

Download: